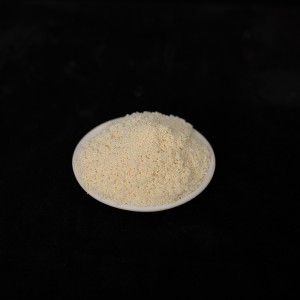

DL510 Strong-Base Acrylic Anion Exchange Resin

DL510 Strong-Base Acrylic Anion Exchange Resin

Typical physical & Chemical characteristics

| Polymer Matrix Structure | Acrylic Crosslinked with DVB |

| Physical Form and Appearance | Clear spherical beads |

| Whole Bead Count | 95% min. |

| Functional Groups | -N+(R3) |

| Ionic Form ,as shipped | Cl |

| Total Exchange Capacity, CL- form, wet, volumetric | 0.8 eeq/l min. |

| Moisture Retention, CL- form | 65-75% |

| Particle Size Range | +1.2 mm <5%, -0.3 mm <1% |

| Average size | 0.65-0.85mm |

| Swelling CL-→ OH- | 15-25% |

| Shipping Weight (approx.) | 650-720 g/l |

| Specific Gravity, moist CL- Form | 1.05-1.08 |

| PH Range, Stability | 0 – 14 |

Suggested Operating Condition

| Maximum Temperature OH- FormCL- Form | 40oC (95oF) max.60oC (140oF) max. |

| Minimum Bed Depth | 0.6m(24inches) |

| Backwash Rate | 50 to 75% Bed Expansion |

| Regenerant Concentration | 2 – 6% |

| Regenerant Flow Rate | 2 to 8 BV/h (0.25 to 1.0gpm/cu/ft.) |

| Regenerant Contact Time | At least 60 minutes |

| Regenerant Level | 112 -300g/L (4 to 10 pounds/ cu/ft.) |

| Displacement Rinse Rate | Same as Regenerant Flow Rate |

| Displacement Rinse Volume | 10 to 15 gallons/cu.ft. |

| Fast Rinse Rate | Same as Service Flow Rate |

| Fast Rinse Volume | 35 to 60 gallons/cu.ft. |

| Service Flow Rate | 10-25m/h (2 to 10 gpm/cu/ft.) |

Hydraulic Properties

(1)Pressure Drop:

The graph above shows the expected pressure loss per foot of bed depth as a function of flow rate, at various temperatures.

(2)Backwash :

After each cycle the resin bed should be backwashed at a rate that expands the bed 50 to 75 percent. This will remove any foreign matter and reclassify the bed. The graph below shows the expansion characteristics of DL 510 in the sodium form.

Write your message here and send it to us